Experienced businesses know the choice to manufacture outside of the country is a strategic decision that requires in-depth consideration of a variety of offshoring advantages. This in mind, there are three misconceptions about the relationship between labor and manufacturing in Mexico business owners should be aware of:

1. Labor in Mexico is "cheap"

Often, when people talk about offshore manufacturing, the first word that comes to mind is "labor." It is a fairly commonly held belief that cheap labor is the No. 1 reason businesses leave the U.S. for foreign countries. Many people think labor in Mexico is just "cheap," and companies take advantage of low wages to save money. The reality is, though, that this could not be farther from the truth. While it is certainly the case that labor prices in Mexico are much lower than both the U.S. and China, the country's workforce has much more to offer than low wages.

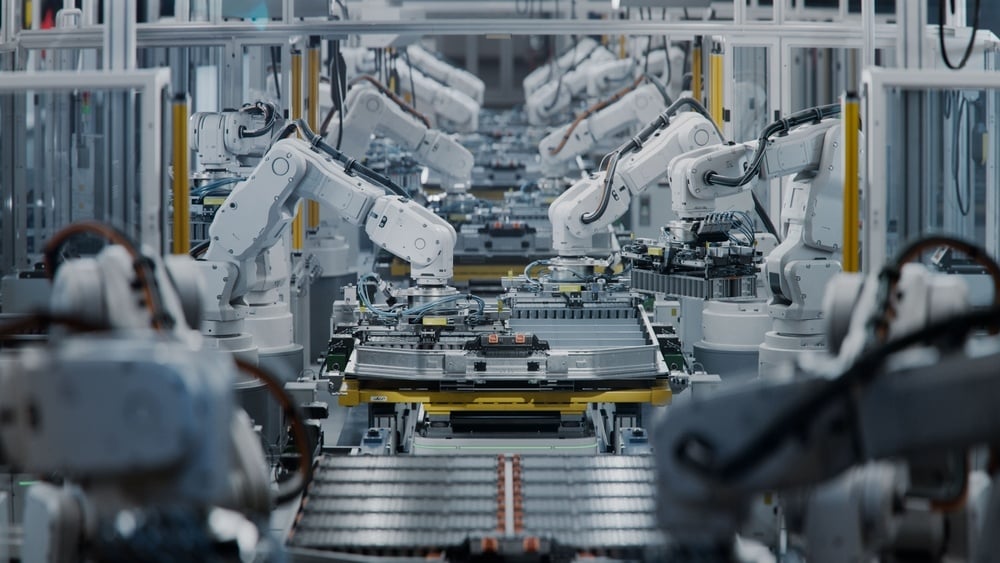

Manufacturers in Mexico create a variety of industries including automotive, medical device and aerospace manufacturing. Not only are these businesses assembling final products from parts manufactured elsewhere, they are executing start-to-finish production and even innovating new technologies.

Labor in Mexico is skilled and highly sustainable.

Labor in Mexico is skilled and highly sustainable.

As a result, skilled labor in Mexico is in high demand because the workforce has the talent and education to meet that need. In fact, Bloomberg shared data from the United Nations Educational, Scientific, and Cultural Organization that found Mexico has roughly 4.9 engineering students per 1,000 people, compared with 3.6 in the U.S. Additionally, government investment in education means Mexico's workforce is likely to improve as far as skills and education are concerned. With the country's focus to advance education in the STEM field, industry culture has been embedded in the career goals of the public. Whether it be from production line operator to plant manager, Mexico's commitment to an industrial future is growing.

2. Labor supply and cost are not stable

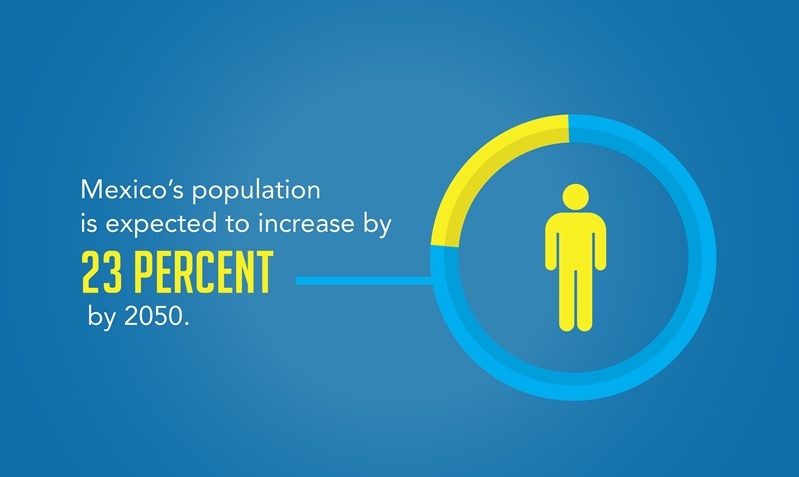

The next misconception about labor is heavily tied to the first. Some businesses are concerned if skill level continues to improve and the middle class continues to grow, the cost of labor will increase and availability will go down. However, Seeking Alpha shared data from the World Bank that should assuage these fears. As it turns out, Mexico's population is expected to increase 23 percent by 2050. This translates to a greater supply of young, working citizens, which will help maintain the country's status as a low-cost manufacturing destination.

3. Businesses only offshore to Mexico for cheap labor

Even if the price of labor were to increase, wages are not the only cost-saving element of manufacturing in Mexico. Businesses in the country also save money due to:

- More efficient supply chains resulting from the country's close proximity to high-demand markets.

- Mexico's participation in the North American Free Trade Agreement, which reduced the cost of and barriers to trade.

- The maquiladora system, which give factories access to duty- tariff-free imports and exports.

It is true that Mexico's low costs bring manufacturers to the country, but the skilled and available workforce provides sustainable business growth. Cost-savings are an extended advantage.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.