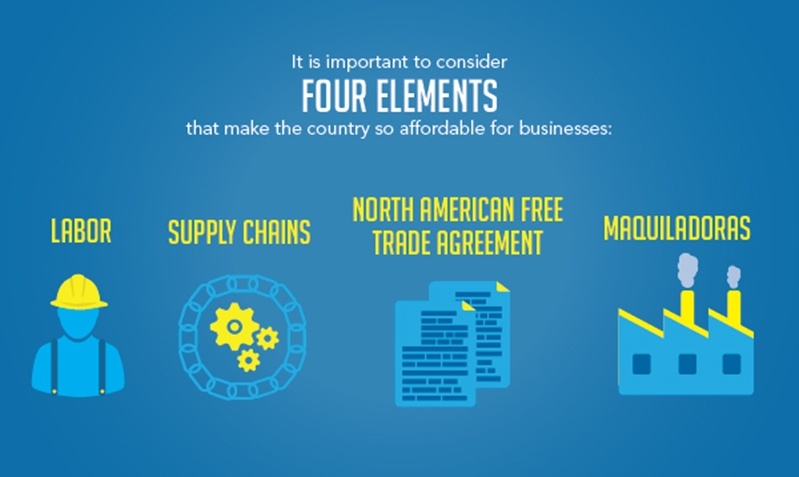

The benefits of manufacturing in Mexico are vast. From skilled labor to advanced infrastructure and the already healthy business environment that exists there, businesses worldwide are making the strategic decision to tap into the country's offshoring advantages. One of the prime factors fueling Mexico's manufacturing boom is cost, as companies have the opportunity to save massive amounts of money and improve their bottom lines by manufacturing there. In order to fully understand why manufacturing in Mexico is a strategic financial move, it is important to consider four elements that make the country so affordable for businesses:

1. Labor

For one, the cost of labor in Mexico is far lower than the U.S, Canada or China. In fact, China was once considered a prime location for manufacturers to tap into cheap labor, but today, prices there have skyrocketed to an almost inaccessible degree. Business Insider cited data from Credit Suisse that revealed the cost of labor in China is now five times more than it was two decades ago, and has now exceeded the price of labor. However, labor in Mexico isn't only cheap, it's high-quality. In an effort to encourage continual manufacturing growth in the country, the Mexican government has evolved its educational infrastructure to create a workforce that is highly skilled in all aspects of manufacturing.

2. Supply chains

For companies attempting to ship manufactured goods to western countries, supply chains can be costly and complicated. Coupled with the low cost of labor, businesses are realizing the economic value of positioning themselves closer to the high-demand markets in both South and North America, especially the U.S. Mexico is in an ideal location for manufacturers to establish partnerships with neighboring economies that create cost savings and logistical efficiencies. As Business Insider noted, the fact that 81 percent of Mexico's exports flow to the U.S. is proof that the country is widely considered a Western economy that manufacturers globally can benefit from tapping into.

One of the key offshoring advantages of manufacturing in Mexico is affordability.

One of the key offshoring advantages of manufacturing in Mexico is affordability.3. North American Free Trade Agreement

When NAFTA took effect in 1994, Mexico underwent major economic changes including privatization of business, energy reform and liberalized trade. In fact, between 1990 and 2000, trade between Mexico and the U.S. increased tremendously. According to Forbes, the U.S. accounted for 69 percent of all Mexican trade in 1990, and grew to 80 percent by 2000. Today, the country's participation in NAFTA is a primary benefit of manufacturing in Mexico because it significantly reduced the costs and barriers to trade, and eliminated prohibitive tariffs that cut into a business's bottom line.

4. Maquiladoras

The maquiladora system makes manufacturing in Mexico unique and affordable. Through this structure, factories are able to import certain materials and equipment duty-free and tariff-free and then export manufactured goods that used those materials. Additionally, the maquiladora system enables companies to work with a shelter services company, which provides logistical, legal, financial and other services that help save costs and improve the efficiency of manufacturing operations.

The Mexican government has a keen interest in encouraging manufacturing within its borders. As a result, manufacturers considering expanding to Mexico can look forward to tremendous cost-savings in terms of labor, supply chains and trade.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.