Bio-based materials, which make up substances polymers, are becoming more prevalent in several manufacturing verticals, according to an article by ThomasNet. Lux Research predicted in the report that global production capacity for these chemicals and materials will double by 2017, a reflection of many manufacturers' sustainability and supply chain diversification initiatives.

Of the verticals incorporating a higher level of biomaterials in their products are the automotive, medical device, and coatings and adhesives industries. Beyond sustainability, biomaterials also serve as a unique alternatives to petrochemicals, allowing many manufacturers to incorporate them into their value chains to mitigate the effects of supply chain disruptions.

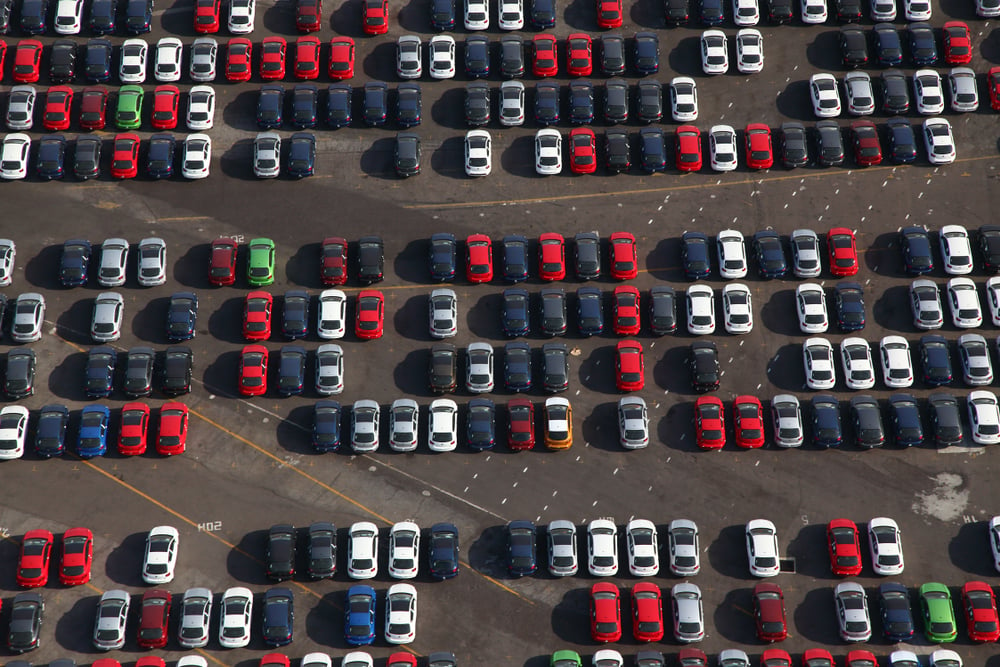

Bio-based materials in automotive manufacturing industry

ThomasNet said in the report that bio-based polymers are expected to grow 18 percent each year largely thanks to automotive manufacturing. General Motors, for example, has been using bio-based polypropylene for Cadillac seats, backing, trim and shelving, while the Ford Flex has biopolymer interior storage bins. Luxury car brands Lexus and Mercedes-Benz have hopped on the biomaterials wagon as well, and Goodyear recently began working with a partner that will help them use the ash resulting from the burning of rice husks to create a new type of silica, a material that improves the traction and fuel efficiency of tires.

ThomasNet's report noted that automobile manufacturing's large volume of parts means that many biomaterials can be integrated into production. Some examples are bio-succinic acid, which partially compose polymers and coatings; farnesene, an unsaturated hyrdrocarbon that is used in fuels and plastic additives; and lactic acid, which is used in goods like chemicals, resins and films.

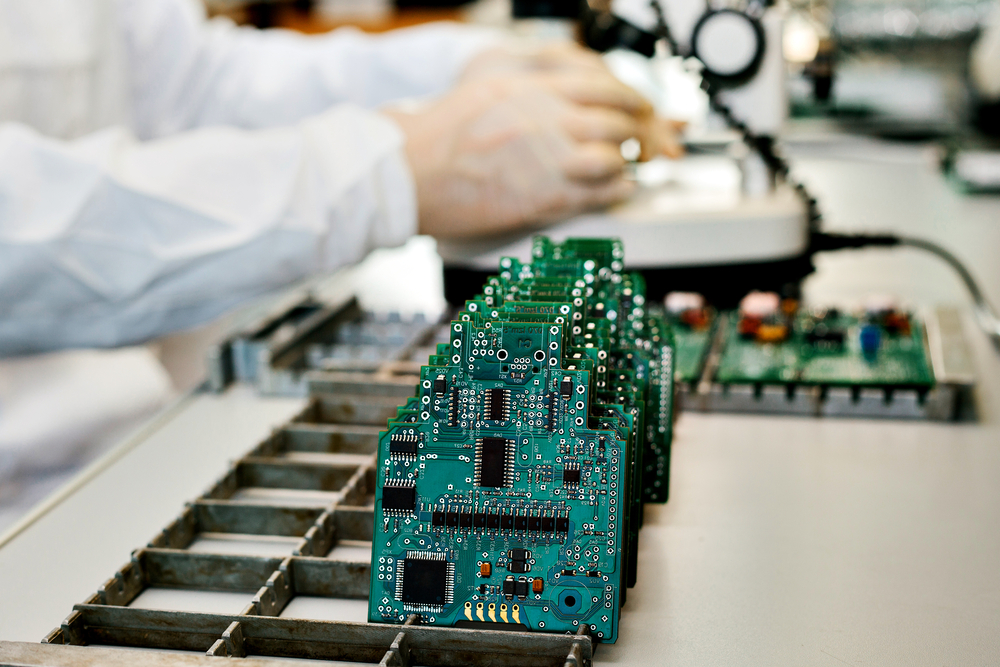

Bio-based materials in medical device manufacturing

These materials have seen a rise in demand in the medical world as well, particularly in implantable device manufacturing. According to a release by Business Wire, Research and Markets stated in its "Biomaterials Market for Implantable Devices - Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2013-2019" report that the success of implants like heart valves, artificial hip joints, dental implants and intraocular lenses has increased the demand for biomaterials as a whole, as they interact directly with biological systems.

Of all the different bio-based materials, the use of polymers is rising the fastest, thanks to their flexibility and longevity. When incorporated into the manufacturing value chain, they offer supply diversification that could potentially assist companies in their quest to counteract disruptions as well as sustainability solutions that could help manufacturers meet green initiatives.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.