In the months since the coronavirus outbreak in Wuhan, China, that has infected more than 70,000 people and led to the deaths of nearly 2,000 people worldwide, countries—and companies—have responded with closures and travel restrictions that are just the latest demonstration of how rapidly global supply chains can be completely disrupted.

Manufacturing in or sourcing materials predominantly from one country to maximize the benefit of nearby suppliers has many advantages. However, this approach also means businesses can easily be disrupted in an instance. After all, disaster can take many forms and strike anywhere. Companies that diversify their manufacturing footprint and supplier base or take a regionalized approach to manufacturing will find they can better regroup when the unexpected happens.

For manufacturing operations in the thick of this viral disruption, this isn’t a lesson to apply someday in the future. Companies looking to minimize the impact of this disruption today will find they can recoup losses faster by establishing a manufacturing presence in Mexico in as little as 30 days through the IMMEX Shelter Program.

The Long-Term Impact of Tariffs and Coronavirus on Global Trade

In 1995, China’s imported and exported goods accounted for approximately 3 percent of global trade. By 2018, that number had jumped to 12.4 percent of global trade. That percentage is weighted more heavily toward exports, as much of the world has come to rely on China as a low-cost base for manufacturing. However, the disruption that has come to trade in recent weeks has demonstrated how short-sighted this singular focus can be.

While U.S. tariffs on China had an impact on global trade throughout 2019, the new coronavirus, or Covid-19, threat has come with less advanced warning. In recent weeks, Chinese factories have idled in the government’s attempt to restrict the spread of the coronavirus. Although factories have since reopened, many of the country’s 288 million migrant workers who had returned to rural hometowns have yet to return to work. A Feb. 17 survey by the American Chamber of Commerce found that 78 percent of companies in the Yangtze River Delta economic corridor still did not have sufficient staff to run a full production line. Over the next several months, 58 percent of companies manufacturing in that area expect demand for their output to be lower than normal.

Analysts predict that if automotive manufacturing facilities remain closed through mid-March, these companies could face production losses of about 32.3 percent in the first quarter of 2020.

Of course, many automotive manufacturers have already faced threats of this nature and have learned that a localized threat can impact their entire production chain. For General Motors, the regionalization “wake up call” came in 2011 when a tsunami in Japan led to the meltdown at a nearby nuclear power plant. Before that time, GM responded to disasters as they came. Following the 2011 disaster, the company invested in risk analytics tools and began holding Blind Spot Workshops to identify the company’s top 30 functional risks. Each of the risks identified now has a mitigation plan and a team in place responsible for managing contingency plans.

However, another factor that has helped GM is that automotive manufacturers have begun to regionalize in the last five to eight years. These companies are establishing manufacturing hubs within their regional markets to more rapidly meet immediate demand and provide better support when disasters do happen. While these steps cannot entirely mitigate the risk impacting the entire automotive supply chain—ultimately, no amount of advanced planning can—it does help set the stage for more flexibility in the company’s response.

Manufacturing in Mexico - The Solution To Your Supply Chain Contingency Plans

Manufacturers concerned by the supply chain turbulence today may consider “nearshoring” some of their manufacturing in closer proximity to the massive U.S. market. In this way, companies can expand their footprint while still benefiting from low labor costs, coupled with less expensive shipping costs.

Establishing a new operation is a significant undertaking that deserves ample advanced planning. However, it is important for companies impacted by today’s supply chain disruptions to know they can establish a factory in Mexico within a manufacturing community in as little as 30 days.

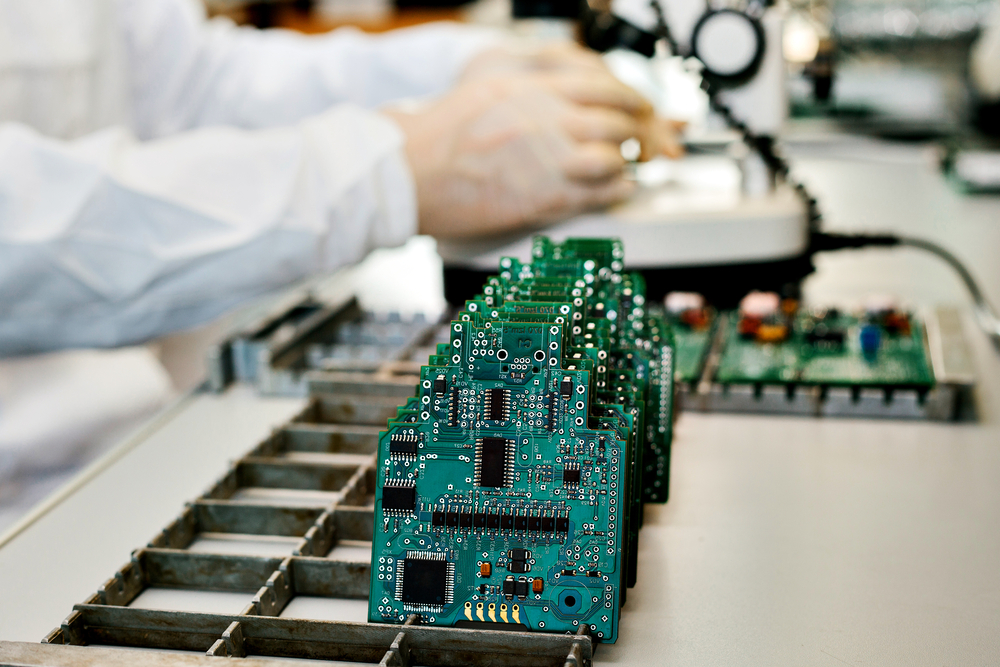

A manufacturing community is far more than an industrial park. Beyond the availability of Class A industrial space for lease, these communities include shelter services that consist of on-site support services and a turnkey legal framework. This allows companies to speed through regulatory red tape, pull together qualified talent fast, and focus on manufacturing their products, without having to deal with the complexities of doing business in Mexico. Typical support services include human resources and payroll administration, import/export expertise, accounting professionals experienced in managing taxes, and reporting for foreign direct investors, facilities management staff, and purchasing experts.

Companies new to operating in Mexico gain a significant benefit in working with an experienced partner that can help navigate the nuances of operating in a new country. Manufacturers that operate as a maquiladora under the IMMEX program can streamline production, reduce legal burdens and lower startup costs.

Ready to make Mexico a part of your manufacturing footprint? To learn more about how manufacturing in Mexico is a long term contingency to China's current trade dynamics, contact us today.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.