General Motors has committed to invest $1 billion in the Ramos Arizpe Manufacturing Complex in the state of Coahuila, Mexico, just outside of the automotive manufacturing hub that is Saltillo, to support its commitment to all-electric car production by 2035. It's a significant step up in its all-electric investment and one that demonstrates just how committed GM is to go all-electric.

As GM continues to push out information about what its future in Saltillo may look like, suppliers are getting a hint at how they can respond. If you're interested in being part of GM's electric future, then launching a manufacturing operation in Saltillo might be the right move for you.

GM is going all electric

GM is aiming to convert all new passenger vehicles to electric power by 2035, with immediate plans to roll out 30 new electric vehicles by 2025. The automotive manufacturer is aiming to sell more than 1 million EVs globally by 2025 toward its goal of becoming the North American market leader in EVs and the global leader in battery and fuel cell technology.

However, GM isn't alone in this commitment. Virtually all major automotive OEMs have made a commitment to shift production from combustion to electric vehicles, and the speed around this transformation is driving major investments.

Back in March 2020, GM had announced plans to invest $20 billion from 2020 through 2025 to cover capital, engineering expenses, and other development costs for its transition to electric vehicle production. By November 2020, that number had crept up to $27 billion, but the rapid shifts driving the marketplace, including major infrastructure and component investments, are pushing automotive manufacturers to dream even bigger. To that end, GM announced in June 2021 a 75% increase in its EV and AV investments from 2020 through 2025, up to $35 billion. This additional investment will support GM's EV transition for fleet vehicles.

"We are increasing our investment to scale faster because we see momentum building in the United States for electrification, along with customer demand for our product portfolio," commented Mary Barra, GM Chair and CEO, in a news release.

Why GM is building electric cars in Mexico

GM has been Mexico's largest car producer since 2018, when it built 830,000 vehicles across its three Mexico production facilities and bumped Nissan into second place. Mexico remains a central part of GM's production strategy, and the focus on supporting the shift to EV production continues exhibited by suppliers in Mexico has cinched the country a key role in GM's EV expansion.

Today, GM has facilities in Ramos Arizpe, where it produces the Chevy Balzer and Equinox; San Luis Potosí, which builds the Chevrolet Equinox and Onix and GMC Terrain; and a plant in Silao that assembles Chevrolet Silverado and Sierra Cabs. The Ramos Arizpe facility, which recently celebrated 40 years of operations, has long played a central role in GM's production and delivery of vehicles in Mexico. In 1983 the facility became GM's first plant in Mexico to export automobiles to the United States, and shortly thereafter began to export vehicles to Asia. Today, the Ramos Arizpe plant exports to more than 40 countries.

Given the global shift to EV production, GM is eager to move ahead. New electric vehicles are slated to begin production at the Ramos Arizpe plant by 2023, although the specific model information has yet to be announced.

Automotive suppliers in Saltillo

The first phase of GM's Ramos Arizpe facility investment is a new painting plant that went live in June 2021. This initial investment is preparing the complex for a forthcoming expansion in the assembly plants and global propulsion systems (GPS), with the goal of converting the complex into GM's fifth North America manufacturing site to produce electric vehicles.

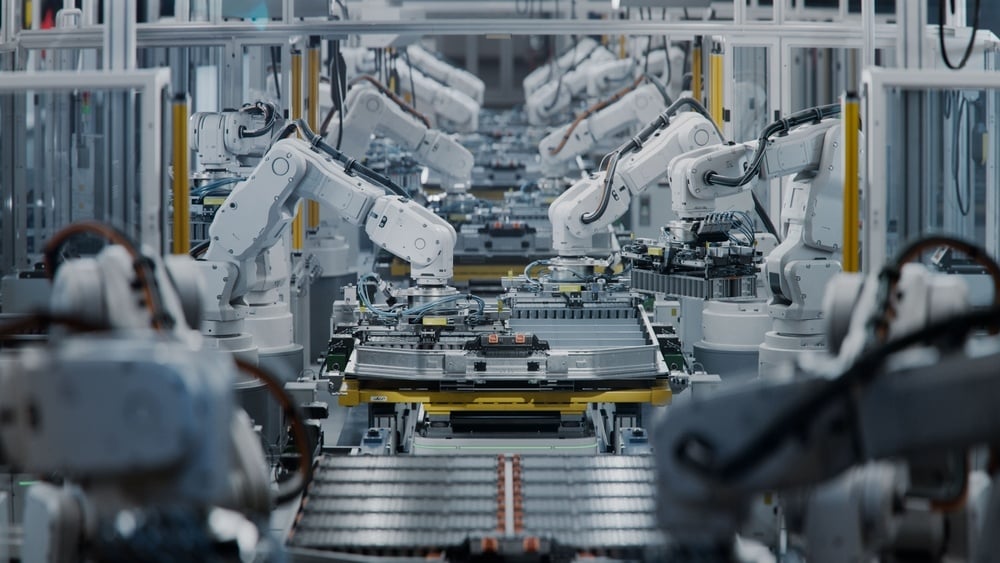

By the second half of 2021, the site is expected to produce batteries and electrical components, including the Ultium Drive propulsion system that powers GM's electric vehicles. The Ultium Drive powertrain is GM's family of five interchangeable drive units and three motors. It brings together components, including castings, gears, and other assemblies that are built with globally sourced parts at GM's global propulsion facilities. Of course, being able to source these new components closer to its manufacturing facility in Ramos Arizpe will help the manufacturer to lower its overall production costs.

Saltillo already holds within its borders a tremendous amount of automotive manufacturing know-how. The city is home to General Motors divisions and two Daimler Chrysler plants and is just a short drive away from the KIA plant in Monterrey. Many Tier 1 suppliers also operate in Saltillo, including Arnecom, Benteler, Brown Corporation, Burgess-Norton, Cooper-Standard, Delphi Technologies, Kay Automotive Graphics, and Lear Corporation.

Part of Saltillo's appeal as an auto manufacturing hub is due to its prime location, just 180 miles from the U.S. border along I-40 and I-57. More of this appeal stems from a skilled workforce experienced in manufacturing for automotive and the surrounding electronics, aerospace, and plastics manufacturing industries.

Now is the time to invest in Saltillo, Mexico

Construction is underway on GM's new facilities within its Ramos Arizpe complex, including improvements to infrastructure materials, dining rooms, medical services, and recreational spaces, among other areas. Now is the time for suppliers ready to support this growth to establish their own operations nearby.

Large corporations like GM aren't the only ones to offer this suite of employee-centric benefits. Some manufacturing communities within Mexico offer on-site amenities meant to attract and retain top talent. In fact, Tetakawi's Zapa Manufacturing Community is the quickest and most cost-effective way to launch an automotive manufacturing operation in Saltillo. More than just an industrial park, Zapa offers a turnkey solution and allows aspiring automotive manufacturers the opportunity to focus on productivity while feeling confident that all regulatory, compliance, and administrative tasks are under control.

If you're ready to establish a maquiladora to support Mexico's growing electric vehicle manufacturing industry, Tetakawi can help. Contact us today.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.