Plastics manufacturing is a big business in Mexico, with an annual production value of approximately USD $20 billion. Producers of PET, PVC, and HDPE, as well as secondary and tertiary plastic materials, support established automotive, aerospace, appliance, and medical device factories in Mexico, in addition to manufacturers across other sectors. As plastics become more integral to manufacturing solutions, the opportunities to strengthen the plastics supply chain in Mexico have grown.

Wondering how to simplify the process of establishing a plastics manufacturing factory in Mexico? The nine steps below provide a roadmap for setting up your plastics factory in Mexico.

1. Select your location

Manufacturers will find different benefits within different Mexican cities. It will be important to identify your priorities early on so that you can determine whether you need a site with, for example, more experienced labor that may be more highly paid or close to a certain supplier, even if it means paying more for suitable real estate.

Many manufacturers start the site selection process by locating near established plastics manufacturing clusters, as these industrial clusters may share infrastructure or training resources. Plastics factories in Mexico can typically be found in states that include Coahuila, Sonora, Querétaro, Nuevo León, Guanajuato, and San Luis Potosí. Querétaro, in particular, has a fast-growing plastics manufacturing scene. It is the fifth most productive industry in the state.

A site selection consultant can help identify a site that may meet your top prioritized needs. Questions to ask to determine the best location include:

- What are typical wages for manufacturers in the area?

- What are typical leasing rates?

- What are typical utility rates?

- Are there government incentives available to support this investment?

- How will I transport goods to my key markets?

2. Determine whether to lease or build a facility

Greenfield development allows a manufacturer to develop a completely custom facility for their needs, but it’s not always necessary. Many plastics manufacturers launching factories in Mexico find ample Class A industrial space available for manufacturers to lease. The most significant benefit of leasing industrial property in Mexico is that it lets manufacturers launch rapidly into the marketplace. Some areas in Mexico are also home to Manufacturing Communities that provide industrial space and onsite shelter services that allow companies to set up their facilities in as little as 30 days.

To determine whether leasing industrial real estate might be suitable for your plastics factory in Mexico, consider asking:

- Is there infrastructure available at my target location to support my manufacturing needs?

- Will fit-outs be cost-effective?

- Is there flexibility in this space to support future growth?

- Is maintenance included in the leasing costs?

Tour industrial parks or Manufacturing Communities in advance to ensure that the space meets your unique manufacturing needs.

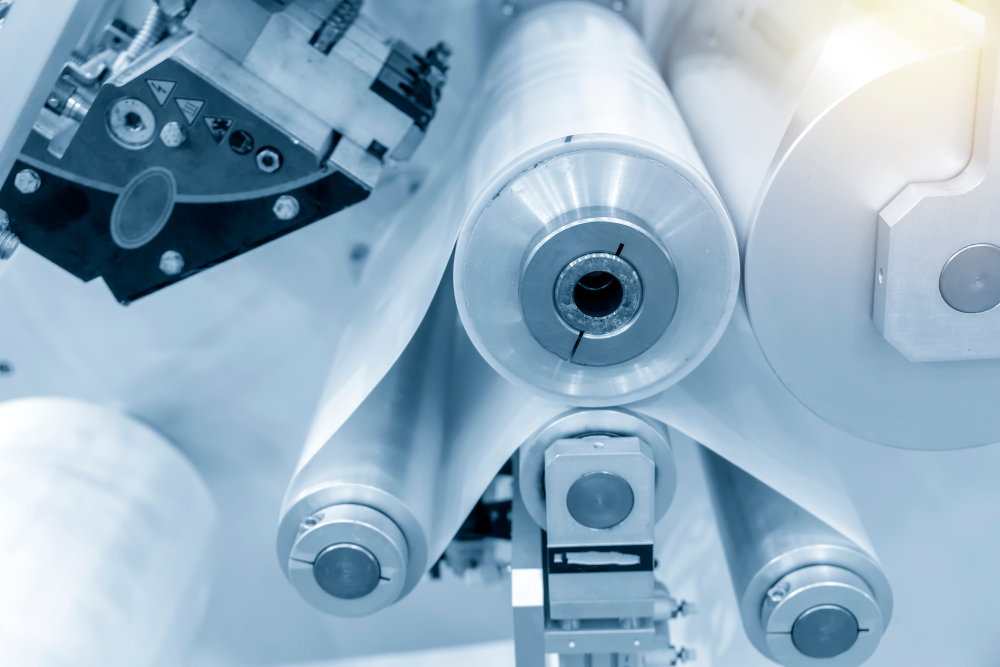

3. Purchase equipment

Whether or not your company is working with a shelter service provider, you’ll need to outfit your plastics factory with the appropriate manufacturing equipment. The good news is that many types of equipment key to producing plastics, from molds to tooling, are made in Mexico. Equipment companies include Platinum Tool Group, a mold designer, engineer, and maintenance firm based in Ontario and with a factory in Ramos Arizpe, Mexico, and Providence Plastics, a Mexico-based company that provides tool design and fabrication.

4. Establish supplier network

Mexico produces more than 4 million tons of various resins annually, from sources including petrochemical company Etileno XXI as well as downstream suppliers such as Osterman Plastics de Mexico, Grupo Primes and Grupo Thermotek. However, plastics factories in Mexico also turn to raw materials that are imported from the United States. This is a cost-effective supply source thanks to Mexico’s duty-free temporary imports policy that helps foreign manufacturers reduce the costs of sourcing raw materials for use in products that will subsequently be exported.

5. Recruit your workforce

One of the chief advantages of manufacturing in Mexico is access to a highly-skilled workforce at a cost-effective rate. However, securing this benefit depends upon a recruitment strategy that is unique to the local area. Manufacturers in Mexico are best served by leveraging a range of recruitment strategies that may be different from the norms of their home country. This may include, for example, posting job ads on Facebook, job boards, and in local newspapers and targeting results by neighborhood. These targeted ads should be supported with rates and benefits that are competitive for the region. Because this information can be difficult to come by, this is an area where it may help to work with a local recruitment expert.

6. Ensure compliance with local regulations

All steps for setting up your plastics factory in Mexico and developing your workforce recruitment plan should be done in compliance with the country’s environmental health and safety (EHS) regulations. Mexico’s Federal Labor Law and Social Security Law establish employees’ right to a safe working environment. Compliance with these regulations is audited by regulatory agencies that include SEMARNAT, CONAGUA, STPS, and PROFEPA. As in most countries, it is important to maintain documentation of compliance.

Companies working with a shelter service provider find this step to be simple. Shelter providers can help Mexican plastic manufacturing companies with their EHS compliance, including securing startup permits, creating environmental impact assessments, and recordkeeping.

7. Make a training plan

Workplace training is a legal requirement for Mexico plastics manufacturers with more than 50 employees. It’s also an excellent way to build the expertise needed to ensure quality products. While many plastics manufacturers in Mexico find in-house training to be sufficient, others benefit from the onsite training facilities available in manufacturing communities. These vocational training sites can help workers gain skills on CNC machines and other complex equipment.

8. Plan your export processes

Planning for export processes should be done early on to help reduce the risk of delays once you’re ready to transport goods. Many manufacturers in Mexico work with a licensed customs broker or a consultant that specializes in customs compliance. These experts can help reduce the risk of any paperwork discrepancies that can potentially delay shipments of goods.

In Mexico, exporters must provide import and export documentation with each shipment, including a completed customs declaration, or pedimento as it is known in Mexico; a commercial invoice; documentation on safety regulation compliance; and a bill of lading.

9. Select the right partner for rapid startup

Given the learning curve that comes from manufacturing in a new country, many companies with plastics factories in Mexico find that they can better speed their launch by working with a shelter service provider. These companies take on much of the administrative and legal burden necessary to get a plastics factory up and running in Mexico, allowing companies to prioritize operational needs.

If you’re ready to take the next step to launch a plastics manufacturing factory in Mexico, contact Tetakawi today.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.