Manufacturing in Mexico has never been better, and many companies are taking advantage of the opportunities the country provides. Some are building maquiladoras - a factory built on specially designated land - to capitalize on the inexpensive labor market. A maquiladora allows companies to take advantage of cheaper taxes and receive more help from the Mexican government. This is a major opportunity for a company that wants to offshore and is seeking a place that is close to the U.S. and still offers well-trained, high quality labor.

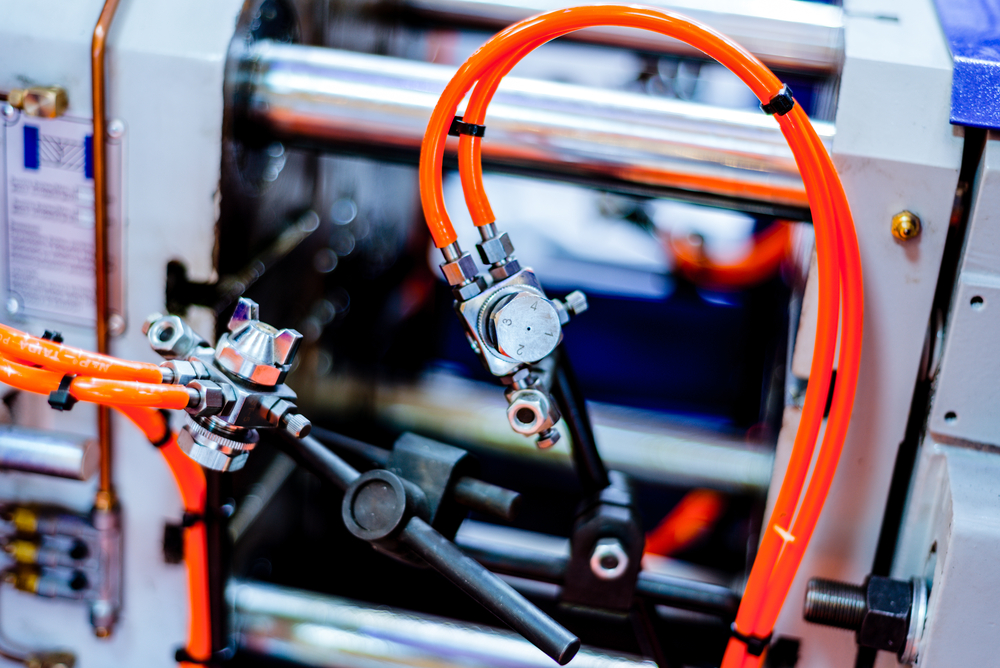

One industry that has a firm base in Mexico is auto manufacturing, while the plastics sector has also expanded with a number of companies making products there. Often, when one industry begins to thrive, related sectors will start to grow in the same area. For example, companies in the plastics industry or steel business that make car parts will sprout up alongside automotive factories. This enables better sourcing opportunities and benefits both businesses.

Car production is well supported in Mexico.

Automotive manufacturing in Mexico

One company that has grown its production in Mexico is Nissan, which is building its new Frontier line of pickup trucks there, Reuters reported. The business expects to make 50,000 units of the 2016 NP3000 Frontier. It will be built in the Mexican state of Morelos. The company has invested $75.39 million in its Mexican factories. Despite being located in Japan, Nissan is able to save a great deal of money by having a maquiladora in Mexico because it can ship the products north to the U.S. without experiencing tariffs. Due to the North American Free Trade Act, shipping between any of the three North American countries is free. Thus, Nissan can simply build its cars in Mexico, and move them to the market in the U.S. and Canada.

Much of the products that Nissan can use to build its cars are available in Mexico already. These include plastics, but also steel and other materials.

The larger manufacturing sector

One example of a business that creates carbon steel is ThyssenKrupp Materials, which has invested $20 million in a new project to its existing factory in Guanajuato, Mexico, Aerospace Manufacturing and Design reported.

"This expansion is important to our business as it positions us as the first Mexico-based facility to offer both aluminum and advanced high-strength steel configured blanking capabilities for our customers," said Christian Dohr, president and CEO of TKM North America, according to AMD.

Many plastics companies have also moved south to Mexico. This includes groups like GW Plastics, Plastics Today cited. This business moved its molding facilities to Queretaro in 2006.

"Following our customers and expanding our footprint in Queretaro meant greater opportunities for us as a supplier," said Justino Barrientos, Mexico sales manager for GW Plastics Today reported.

Companies that take advantage of nearshoring to Mexico have many advantages, and being part of a slowly growing supply chain is one of them.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.