Many major automotive manufacturers have been flocking to Mexico to capitalize on the low-cost manufacturing and skilled labor driving the country's auto-making boom, and Mitsubishi is no exception. After a $33 million investment back in April 2013, the Japanese car maker began operating its new plant last week.

Mitsubishi's new Mexican subsidiary

Mitsubishis's new Mexican subsidiary, officially named Mitsubishi Electric Automotive de Mexico, S.A. de C.V., is located in El Marques, Queretaro and produces automotive parts like alternators, starter motors and multimedia products. According to a recent report by RTT News, the manufacturing and sales base is partially owned by Mitsubishi Automotive America, Inc. and exists to expand the company's auto parts business in the Americas.

Mitsubishi hopes that strategic moves such as this will up annual sales to the equivalent of $275 million by 2017. By expanding to Mexico and subsequently securing a better foothold in the local supply chain, the automaker anticipates that the new plant will mean a better, more efficient business structure for the American market.

"With the continued turnaround and growth of the automotive industry in both North and South America, building this plant will increase our capacity and allow us to better compete and meet the needs of our customers throughout this hemisphere," said Mike DeLano of Mitsubishi Electric Automotive America, Inc. in Mitsubishi's recent release.

North American consumption repairs faltering overseas units

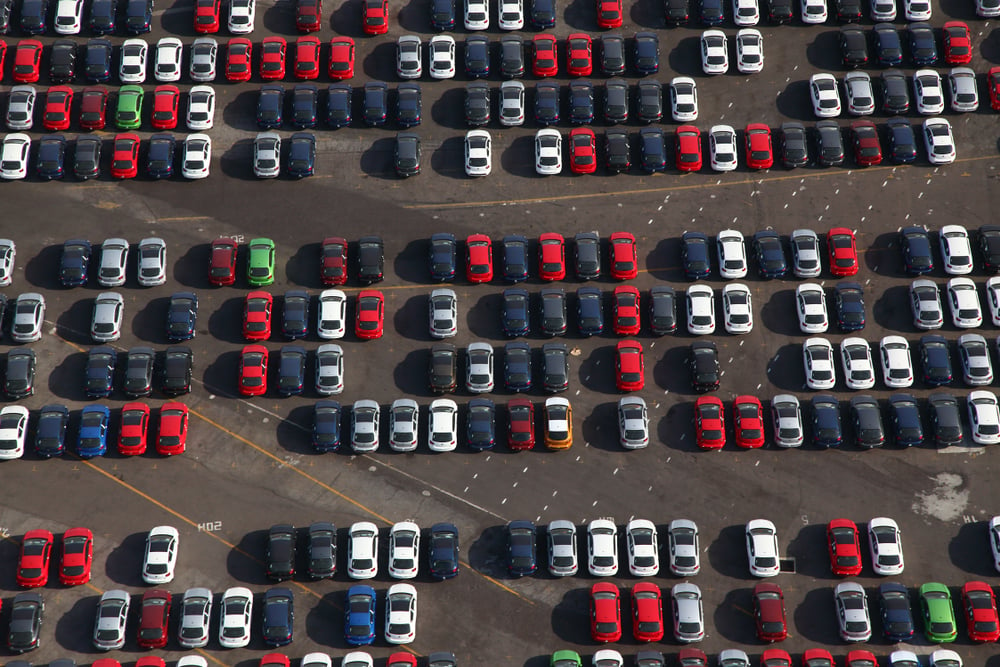

Meanwhile, the U.S. is experiencing its strongest car consumption pace in years. The Wall Street Journal reported that domestic sales rose 9 percent last month when compared to September 2013, reaching what is nearly a decade high and causing automakers producing for the North American market to anticipate a significant growth in profits.

While this growth is lacking in overseas countries, manufacturers are still optimistic. North American profits provide global companies with a viable way to offset problems elsewhere. The profit made from U.S. new car demand can patch up the demand lag in Europe and Asia while financing global market share push in important emerging markets. According to Ford, these emerging markets, not including China, represent a $1 trillion growth opportunity for the industry through 2020 and 55 percent of the industry's growth through 2030, not including China. This exponential global growth cannot be achieved without garnering significant products in the U.S., however.

Manufacturing in Mexico provides auto manufacturers like Mitsubishi with a way to meet increased consumer demand in the United States at a lower cost at more efficient pace than they would offshoring in overseas markets, ultimately allowing them to repair their lagging units abroad. While there are several methods for expanding to Mexico, offshore shelters like the Offshore Group offer an easier, less time intensive outsourcing alternative to companies who want to capitalize on Mexico's skilled labor, reduced costs, market proximity and strong infrastructure.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.