Several adaptive and innovative production technologies have made their way onto the scene as of late, providing companies with a way to reduce manufacturing costs and create a much higher-performing and competitive manufacturing industry as a whole. While many automakers have dipped their toes in the high-tech waters, Ford was the first to release an official video series detailing the ways that the industry is changing.

Manufacturing innovations at Ford

Ford recently released a series of videos demonstrating some of the new technology the team has been integrating into their production processes. From video gaming and virtual manufacturing to 3D printing, these techniques have disrupted the manufacturing sector in almost every industry through their ability to create better, stronger, faster parts.

One of the automaker's videos explores its virtual factories, which they've said have reduced manufacturing-related issues by 90 percent since 2002. Using them, Ford has been able to simulate the manufacturing process digitally, which has improved production efficiency and subsequent speed to market. Virtually optimizing the assembly has also allowed the company to significantly increase worker safety.

A second strategy the company delved into in its video series was its use of video simulation technology. This allows for the testing of new designs and other options before cars are even physically produced, accelerating engineering and design processes and allowing for global collaboration. Meeting market demand in a faster and more efficient manner in this way does more than create more competitive manufacturing - it also means a much higher quality product.

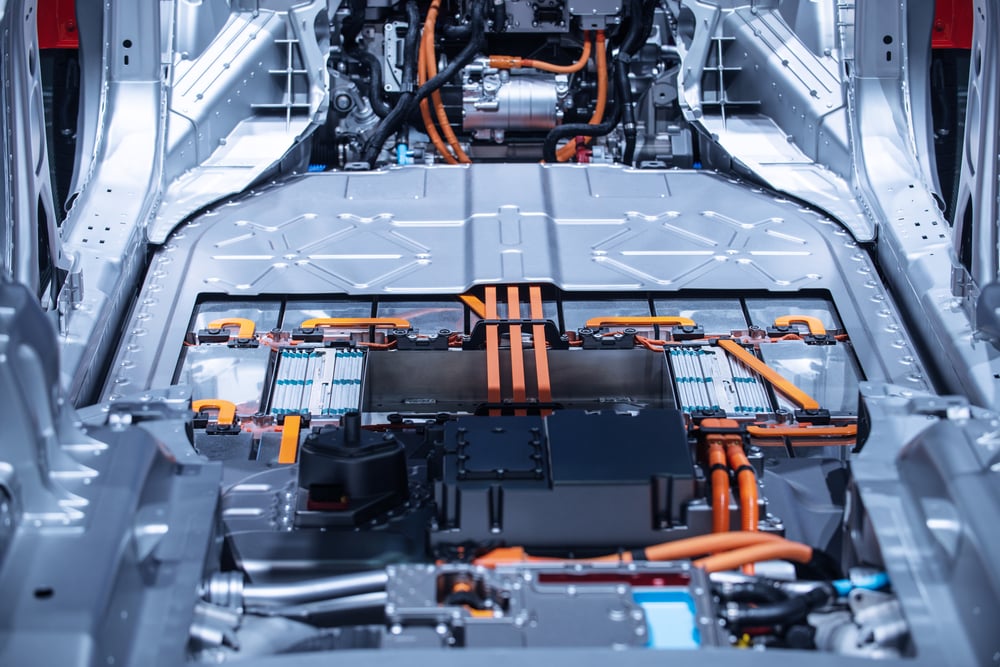

In their final video, Ford explained how they use additive manufacturing to design digital prototypes. This enables product testing long before beginning the actual manufacturing process and creates materials that are both infinitely lighter and infinitely stronger than their traditional counterparts. The effects of additive manufacturing have reached far beyond automotive testing, however.

Changing the landscape of manufacturing and engineering

Additive manufacturing, also known as 3D printing, has already had a lasting effect on the aerospace, medical and military industries as well.

According to the Green Bay Press Gazette, a liquid mixture of metals and polymers are squeezed through a nozzle and "written" layer by layer to create items that traditional manufacturing cannot. The process, called Projection Microstereolithography, results in strong, ultra-light materials that are revolutionizing manufacturing entirely. By enabling the production of things that were once impossible to make and significantly lowering the costs associated with complex items, 3D printing has given engineers and manufacturers an unlimited bank of creative license.

Items such as these have ranged from nuclear weapon safety devices to 3D cars to microlattices, or geometric building blocks similar to cells in the human body that are strong enough to withstand thousands of times their own weight. Engineers speculate they will soon be able to make antennas with sensors that can detect and quantify injury and nearly indestructible armor for soldiers on the battlefield.

Additive manufacturing has also had a profound effect on the production line thus far. While traditional assembly lines dictate the continuous construction of one item, 3D printing means that many different things can be made in one plant - and at a significantly faster pace. Manufacturers will be able to upload a job to the system and press print immediately. Ideally, each printed piece will one day come with a digital finger print that will carry its history and structural integrity along with it to each stop on the supply chain.

While it is expected that 3D printing will help revolutionize manufacturing as we know it within the next decade, engineering.com reports that most of today's computer-aided design tools have not yet totally adapted to additive manufacturing's capabilities. In the future, technology will be able to find and suggest optimized parts or combinations of parts that will quicken, refine and improve manufacturing as a whole.

The manufacturing landscape is changing across the automotive, aerospace, and medical device sectors alike, and the production possibilities are becoming increasingly endless. While it is unclear what the future of the industry specifically holds, we can expect to see radical technological advancements alongside low-cost manufacturing and an increasingly safer, more efficient supply chain.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.