From their beginnings in the early 1960s, maquiladoras have shaped Mexico's economy, bringing growth in employment, trade, and cross-border commerce. What started as a border-zone assembly program has evolved into one of the Western Hemisphere's largest manufacturing ecosystems, with more than 6,550 active facilities, 3.2 million workers, and over $840 billion in annual trade between the US and Mexico.

The success of the maquiladora system has led to powerful competitive advantages for manufacturers around the world. But the model has also changed considerably since those early days in Tijuana. In this article, we trace how maquiladoras started, how they evolved through NAFTA and IMMEX, and where the model is headed as nearshoring, tariffs, and the 2026 USMCA review reshape the landscape.

What Is a Maquiladora? Definition and Meaning

The term "maquiladora" comes from the Spanish word "maquila," which originally referred to the portion of grain a miller kept as payment for grinding wheat in medieval Spain. The word has since evolved to describe a manufacturing operation that processes raw materials and resources into finished products for export.

In practice, a maquiladora is a factory in Mexico owned by a foreign company that imports raw materials duty-free, manufactures products, and exports them, typically to the United States or Canada. The parent company retains full control over manufacturing processes, product quality, and intellectual property. Day-to-day administrative operations, including workforce management, regulatory compliance, and facility maintenance, are typically handled locally, often through a shelter services provider.

Today, maquiladoras operate under Mexico's IMMEX program (Industria Manufacturera, Maquiladora y de Servicio de Exportacion), which modernized the original maquiladora framework in 2006. As of early 2025, INEGI reports approximately 6,550 active IMMEX-registered establishments in Mexico, employing more than 3.2 million workers and generating nearly 90% of the country's manufactured exports.

Maquiladoras can be established virtually anywhere in Mexico and produce nearly any type of manufactured good, with narrow exceptions for firearms and nuclear components. The breadth of the program reflects Mexico's evolution from a border-zone assembly economy into a diversified, full-scale manufacturing partner for global supply chains.

Where Are Maquiladoras Located in Mexico?

Maquiladoras are concentrated along Mexico's northern border with the United States, though significant manufacturing activity has expanded into central and western regions over the past two decades.

The six northern border states account for the majority of IMMEX-registered operations. Baja California leads with roughly 17.6% of all establishments, followed by Nuevo Leon at 13.5%, Chihuahua at 9.1%, and Coahuila at 6.8%. Sonora and Tamaulipas round out the border state corridor.

Much of this activity clusters around twin-city pairs that straddle the border, where proximity to American highways, rail networks, and distribution centers creates natural logistics advantages. Key corridors include Tijuana/San Diego, Ciudad Juarez/El Paso, Nuevo Laredo/Laredo, Reynosa/McAllen, and Nogales/Nogales. The Laredo port of entry alone handled $339 billion in two-way trade in 2024, making it the single largest trade gateway in the United States.

Beyond the border zone, Mexico's Bajio region, including Guanajuato, Queretaro, and Jalisco, has emerged as a major manufacturing hub, particularly for automotive, aerospace, and electronics production.

Modern manufacturers increasingly operate within dedicated Manufacturing Campuses that consolidate workforce recruitment, regulatory compliance, logistics infrastructure, and operational support in established industrial zones. These campuses eliminate the vendor fragmentation that characterized traditional maquiladora operations, where a manufacturer might coordinate separately with a landlord, staffing agency, customs broker, and logistics provider. Tetakawi operates five such campuses across Sonora (Guaymas, Empalme, Hermosillo), Coahuila (Saltillo), and Mazatlan, supporting more than 60 active manufacturers.

Maquiladoras by the Numbers

Mexico's maquiladora sector has grown into one of the largest manufacturing ecosystems in the Western Hemisphere.

|

Metric |

Figure |

Source |

|

Active IMMEX establishments |

~6,550 (Feb 2025) |

INEGI |

|

Total IMMEX employment |

3.24 million workers |

INEGI |

|

Mexico total exports (2024) |

$617 billion |

INEGI |

|

Manufactured goods as % of exports |

~90% |

INEGI |

|

US-Mexico goods trade (2024) |

$840 billion (record) |

US Census Bureau |

|

Mexico rank as US trade partner |

#1 (2023 and 2024) |

USTR |

|

FDI into Mexico (Jan-Sep 2025) |

$40.9 billion |

Secretaria de Economia |

|

Manufacturing share of Mexico GDP |

~19% |

World Bank |

The benefits of operating a maquiladora in Mexico

Maquiladoras offer tax, labor, and other benefits to their foreign-owned companies. The ownership company can import raw materials into Mexico duty- and tariff-free, so long as they then export the final product. Companies with administrative headquarters in the United States often are able to lower their overall manufacturing costs through the employment of a Mexico workforce at more competitive wages.

Companies can lower their operational costs while boosting production. The start-up process and administrative management are easily navigated, especially when working with a shelter service provider.

1960s-1980s: The origin of the maquiladora program

Maquiladoras in Mexico can trace their origins to the National Border Industrialization Program of 1964. This initiative by the Mexican government aimed to encourage foreign investment to stimulate domestic markets. Under the maquiladora program, all raw materials imported into the country for manufacturing purposes became duty-free with one stipulation: the final product had to be exported back to the country of origin or to a third party.

Shortly after the program's launch, a handful of U.S. electronics companies set up shop in the border town of Tijuana. Unfortunately, the value of the Mexican peso at the time offered little incentive to manufacture under the maquiladora model.

1970s-1980s: The growth of maquiladoras in Mexico

This began to change over the next decade. Mexico borrowed a great deal of money in the 1970s to fuel the exploration of oil resources, and inflation rose steadily with the peso's devaluation. Bankruptcy in the 1980s created an urgent need for hard currency, a need that was eagerly met by the U.S. manufacturers that wanted to reduce labor costs in an increasingly competitive global economy.

The Mexican government recognized how important maquiladoras in Mexico could be to rebuild their financial infrastructure, so they began to lift foreign investment restrictions and production laws. Changes to the Maquiladora Program were laid out in 1989 through the "Decree for Development and Operation of the Maquiladora Industry." Under these revisions, the program allowed maquiladoras to sell up to 50 percent of their products to domestic markets in Mexico.

1990s-2000s: NAFTA’s impact on the maquiladora program in Mexico

Despite revisions to laws and regulations, maquiladoras in Mexico remained a relatively untapped resource until 1994 with the passing of the North American Free Trade Agreement (NAFTA). When NAFTA implementation began, it created the world's largest free trade area. NAFTA connected more than 400 million people producing over $11 trillion in goods and services. The maquiladora program also increased Mexico's visibility as a potential manufacturing partner for companies in the U.S. and around the globe.

Under NAFTA, maquiladoras could make use of waived Mexican import duties and receive preferential rates on duties for specific products and resources. These benefits made it much easier for the manufacturing industry in Mexico to grow.

Two-way trade with the U.S. under NAFTA was a catalyst for major economic growth, accounting for $345 billion in 2014. By 2024, that figure had grown to a record $840 billion in goods trade, the highest annual total between any two nations. It is because of NAFTA, and its replacement, the U.S.-Mexico-Canada Agreement, that the two-way trading partnership of manufactured goods, specifically automotive and aerospace, is possible.

2000s-2018: Modern maquiladoras under IMMEX

In 2006, the IMMEX Program (which stands for the Maquiladora, Manufacturing and Export Services Industry) was established to offer maquiladora companies additional benefits. The program's development reduced costs, created new ways for companies to operate, and modernized maquiladora establishment procedures. It also created the structure for how maquiladoras operate today.

Under IMMEX, foreign investors can reap the maquiladora advantages by registering as an IMMEX company. There are five distinct IMMEX registration options: Holding Company, Industrial, Services, Shelter, and Outsourcing. These business options are selected based on the type of product or service being exported

2019-2020s: Growth of Maquiladoras Today

The USMCA, which entered into force on July 1, 2020, replaced NAFTA, providing foreign manufacturers and Mexican laborers with new work protections. Modernized elements of the program further eased the free flow of North American trade. Among other elements, USMCA increased the total amount of content in automobiles that must originate in North America to qualify for production incentives.

These changes provided additional incentives for manufacturers to expand into Mexico at a time when many companies were rethinking their global manufacturing footprint. Companies once focused on manufacturing in China or Southeast Asia to serve a U.S. customer base found themselves at a distinct disadvantage due to global shipping disruptions.

Today, more companies are making a Mexico manufacturing operation a key part of their strategy to better serve their American customers.

2021-2026: Nearshoring, Record Trade, and New Tariff Pressures

The COVID-19 pandemic exposed critical vulnerabilities in global supply chains built around low-cost Asian manufacturing. Factory shutdowns, port congestion, and weeks-long shipping delays forced manufacturers to rethink where and how they produced goods for the North American market. The result was a nearshoring wave that reshaped Mexico's industrial landscape.

Mexico overtook China as the United States' largest trading partner in 2023 and maintained that position in 2024, when bilateral goods trade hit a record $840 billion. Foreign direct investment surged alongside the trade numbers. In the first nine months of 2025 alone, Mexico attracted $40.9 billion in FDI, with new greenfield investment flows tripling compared to the prior year. Manufacturing accounted for 43% of that investment.

This growth did not go unchallenged. In February 2025, the United States imposed 25% tariffs on Mexican goods that do not comply with USMCA rules of origin. The practical impact has been more nuanced than the headline rate suggests: approximately 85% of Mexico's exports to the US qualify under USMCA and continue to enter duty-free. For manufacturers operating under IMMEX with proper shelter services and compliance infrastructure, USMCA qualification has become a core operational requirement rather than an optional advantage.

The USMCA joint review, scheduled to begin July 1, 2026, will determine whether the agreement continues, is renegotiated, or is allowed to expire. For manufacturers with operations in Mexico, the review underscores the importance of maintaining compliant operations through established frameworks like the IMMEX shelter program, where permanent establishment risk is managed by the shelter operator rather than the foreign manufacturer.

The Next Chapter: From Maquiladoras to Manufacturing Campuses

The maquiladora model solved a specific problem in the 1960s: give foreign manufacturers duty-free access to Mexican labor markets. Six decades later, the operating environment has changed dramatically. Supply chains are more complex, regulatory requirements under USMCA and IMMEX demand tighter compliance, and workforce competition across northern Mexico has made talent retention as important as cost savings.

These pressures have pushed the model forward. Today, the most competitive manufacturers in Mexico operate within shelter services frameworks that go well beyond the original maquiladora arrangement. Rather than simply providing a tax structure and a factory floor, the manufacturing campus model bundles workforce recruitment, regulatory compliance, logistics infrastructure, and operational support into a single integrated environment.

The distinction matters because traditional maquiladora operations typically require the manufacturer to coordinate with multiple independent vendors: a landlord for facility space, a staffing agency for labor, a customs broker for trade compliance, and a logistics provider for freight. Each vendor adds a layer of management overhead. The manufacturing campus model consolidates those functions under one operational platform, allowing the manufacturer to focus on production while the campus operator handles the rest.

Frequently Asked Questions About Maquiladoras

What is a maquiladora in simple terms?

A maquiladora is a factory in Mexico owned by a foreign company that imports raw materials duty-free, manufactures products, and exports them. Most maquiladoras produce goods for the US market and operate under Mexico's IMMEX program, which provides the legal framework for duty-free imports and streamlined customs compliance. As of 2025, there are approximately 6,550 active IMMEX-registered establishments employing more than 3.2 million workers.

Where are maquiladoras located in Mexico?

The majority of maquiladoras are in Mexico's six northern border states: Baja California, Chihuahua, Coahuila, Nuevo Leon, Sonora, and Tamaulipas. Key manufacturing corridors include Tijuana/San Diego, Ciudad Juarez/El Paso, and Nuevo Laredo/Laredo. Significant activity has also expanded into central Mexico's Bajio region, including Guanajuato, Queretaro, and Jalisco, particularly for automotive and aerospace production.

What is the difference between a maquiladora and a regular factory?

The key difference is the trade framework. A maquiladora operates under Mexico's IMMEX program, which allows duty-free import of raw materials for manufacturing, provided the finished goods are exported. A regular factory in Mexico pays standard import duties. Maquiladoras are also typically foreign-owned and export-oriented. Many today operate through shelter services providers that handle regulatory compliance, workforce management, and administrative operations on behalf of the foreign manufacturer.

How does the IMMEX program work for maquiladoras?

IMMEX is the Mexican government program that provides the legal and tax framework for maquiladora operations. Companies register under one of five modalities: Holding Company, Industrial, Services, Shelter, or Outsourcing. Registration allows duty-free temporary import of raw materials, components, and equipment used in manufacturing for export. The Shelter modality is particularly relevant for foreign manufacturers entering Mexico, as it allows a Mexican shelter operator to hold the IMMEX registration and assume administrative, legal, and compliance responsibilities on behalf of the foreign company.

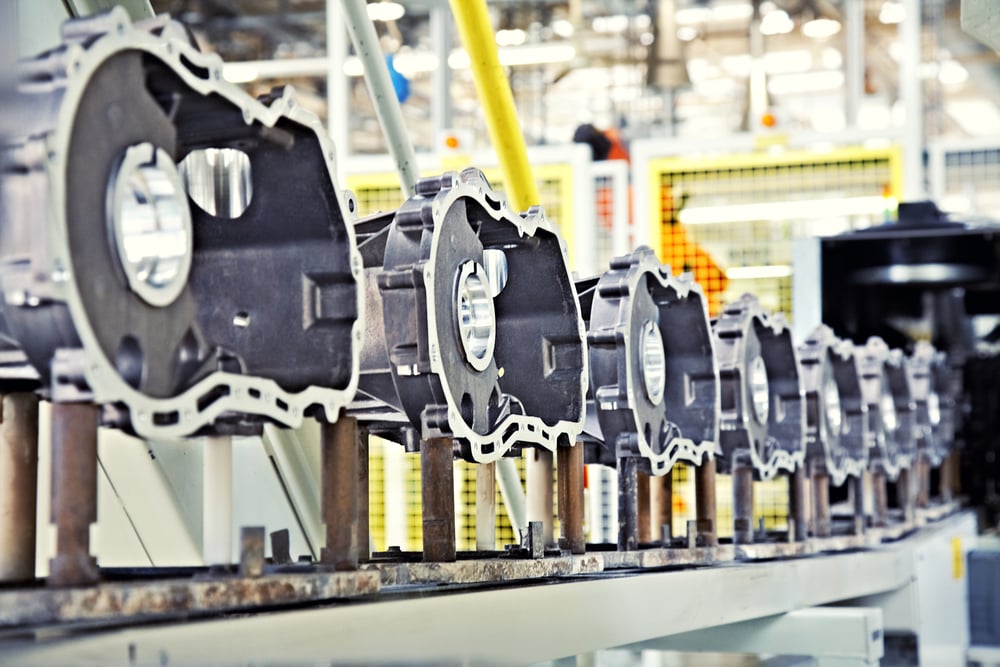

What industries use maquiladoras in Mexico?

Automotive manufacturing is the largest sector, with vehicles accounting for $136 billion in Mexican exports. Machinery ($103 billion) and electronics ($97 billion) follow. Medical device manufacturing has grown significantly, reaching $22.8 billion. Other major sectors include aerospace, plastics, furniture, and consumer goods. The breadth of industries reflects Mexico's evolution from a low-cost assembly location to a diversified manufacturing economy.

How has the maquiladora model evolved since NAFTA?

Three major shifts have transformed the model since NAFTA launched in 1994. First, the IMMEX program (2006) modernized the regulatory framework. Second, USMCA (2020) tightened rules of origin, particularly for automotive, making compliance infrastructure more critical. Third, the post-COVID nearshoring wave drove record investment and trade, pushing Mexico to become the US's #1 trading partner in 2023. Today's operations look very different from the border-zone assembly plants of the 1990s, with many manufacturers operating within integrated Manufacturing Campuses that provide workforce, compliance, and logistics support under one roof.

Setting up a maquiladora in Mexico?

Given its history, the maquiladora model is an easily accessible method for establishing new operations or expanding an existing business into Mexico. If you're ready to explore the benefits of today's modern maquiladora program, Tetakawi can help. Reach out today with questions or to get started. Together, we'll work to make manufacturing in Mexico a reality for your company.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.