From their beginnings in the early 1960s, maquiladoras have shaped Mexico’s economy, bringing growth in employment, trade, and service. In this post, we’ll take a look at how maquiladoras started and how they have evolved to create the modern industry we know today.

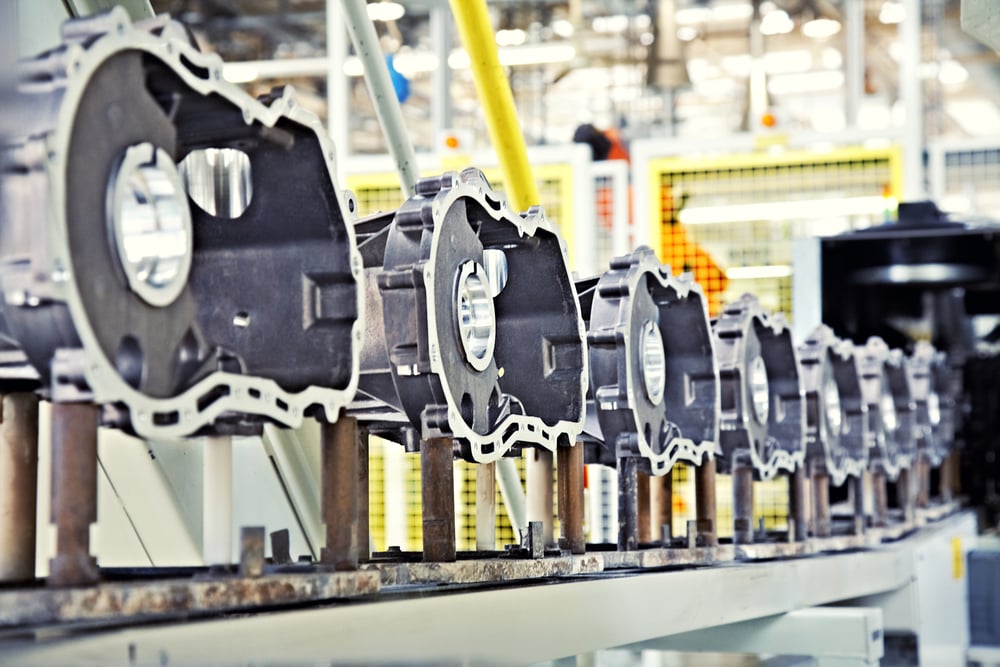

Maquiladoras in Mexico are manufacturing plants owned by foreign direct investors. Companies that use maquiladoras are able to benefit from tax advantages offered by Mexico’s federal government. In return, Mexican workers gain access to manufacturing jobs. The success of the maquiladora system has led to powerful competitive advantages for manufacturers around the world.

Since the early 1960s, maquiladora companies have shaped Mexico’s economy. This unique arrangement has driven growth in business employment and cross-border trade. The maquiladora program has also faced challenges that have driven improvements to the model. In this article, we’ll take a look at how maquiladoras started and how they have evolved to create the modern industry we know today.

What are maquiladoras in Mexico?

The term “maquiladora” is derived from the word “maquila,” which originally referred to the process of grinding wheat into flour in medieval Spain and the grain retained by the miller as compensation. The word has since evolved to represent today’s modern meaning: a manufacturing operation that processes raw materials and resources into finished products to be sold in countries other than where they were manufactured.

Typically, management of the maquiladora’s day-to-day operations is handled by Mexican-based management. However, the ownership company controls all manufacturing expertise, operations know-how, and long-term strategic goals. The ownership company retains complete control of its product and quality processes.

Maquiladoras can be built virtually anywhere in Mexico. There are nearly no limits on the types of goods that can be manufactured (excluding firearms and products with nuclear components).

The benefits of operating a maquiladora in Mexico

Maquiladoras offer tax, labor, and other benefits to their foreign-owned companies. The ownership company can import raw materials into Mexico duty- and tariff-free, so long as they then export the final product. Companies with administrative headquarters in the United States often are able to lower their overall manufacturing costs through the employment of a Mexico workforce at more competitive wages. Companies can lower their operational costs while boosting production. The start-up process and administrative management are easily navigated, especially when working with a shelter service provider.

1960s-1980s: The origin of the maquiladora program

Maquiladoras in Mexico can trace their origins to the National Border Industrialization Program of 1964. This initiative by the Mexican government aimed to encourage foreign investment to stimulate domestic markets. Under the maquiladora program, all raw materials imported into the country for manufacturing purposes became duty-free with one stipulation: the final product had to be exported back to the country of origin or to a third party.

Shortly after the program’s launch, a handful of U.S. electronics companies set up shop in the border town of Tijuana. Unfortunately, the value of the Mexican peso at the time offered little incentive to manufacture under the maquiladora model.

1970s-1980s: The growth of maquiladoras in Mexico

This began to change over the next decade. Mexico borrowed a great deal of money in the 1970s to fuel the exploration of oil resources, and inflation rose steadily with the peso’s devaluation. Bankruptcy in the 1980s created an urgent need for hard currency – a need that was eagerly met by the U.S. manufacturers that wanted to reduce labor costs in an increasingly competitive global economy.

The Mexican government recognized how important maquiladoras in Mexico could be to rebuild their financial infrastructure, so they began to lift foreign investment restrictions and production laws. Changes to the Maquiladora Program were laid out in 1989 through the “Decree for Development and Operation of the Maquiladora Industry. ”Under these revisions, the program allowed maquiladoras to sell up to 50 percent of their products to domestic markets in Mexico.

1990s-2000s: NAFTA’s impact on the maquiladora program in Mexico

Despite revisions to laws and regulations, maquiladoras in Mexico remained a relatively untapped resource until 1994 with the passing of the North American Free Trade Agreement (NAFTA). When NAFTA implementation began, it created the world's largest free trade area. NAFTA connected more than 400 million people producing over $11 trillion in goods and services. It The maquiladora program also increased Mexico's visibility as a potential manufacturing partner for companies in the U.S. and around the globe.

Under NAFTA, maquiladoras could make use of waived Mexican import duties and receive preferential rates on duties for specific products and resources. These benefits made it much easier for the manufacturing industry in Mexico to grow.

Two-way trade with the U.S. under NAFTA was a catalyst for major economic growth, accounting for $345 billion in 2014. It is because of NAFTA—and its replacement, the U.S.-Mexico-Canada Agreement—that the two-way trading partnership of manufactured goods, specifically automotive and aerospace, is possible.

2000s-2018: Modern maquiladoras under IMMEX

In 2006, the IMMEX Program (which stands for the Maquiladora, Manufacturing and Export Services Industry) was established to offer maquiladora companies additional benefits. The program’s development reduced costs, created new ways for companies to operate, and modernized maquiladora establishment procedures. It also created the structure for how maquiladoras operate today.

Under IMMEX, foreign investors can reap the maquiladora advantages by registering as an IMMEX company. There are five distinct IMMEX registration options: Holding Company, Industrial, Services, Shelter, and Outsourcing. These business options are selected based on the type of product or service being exported.

With its inception, IMMEX further incentivized manufacturers to expand into Mexico and strengthened Mexican exports. In just over a decade, the program led to a 99 percent increase in export trade, from $210 billion in 2005 to $419 billion in 2017. That growth continues today.

2019-2020s: Growth of maquiladoras today

In 2019, the USMCA replaced NAFTA, providing foreign manufacturers and Mexican laborers with new work protections. Modernized elements of the program further eased the free flow of North American trade. Among other elements, USMCA increased the total amount of content in automobiles that must originate in North America to qualify for production incentives.

These changes provided additional incentives for manufacturers to expand into Mexico at a time when many companies were rethinking their global manufacturing footprint. Companies once focused on manufacturing in China or Southeast Asia to serve a U.S. customer base found themselves at a distinct disadvantage due to global shipping disruptions. Today, more companies are making a Mexico manufacturing operation a key part of their strategy to better serve their American customers.

Setting up a maquiladora in Mexico?

Given its history, the maquiladora model is an easily accessible method for establishing new operations or expanding an existing business into Mexico. If you're ready to explore the benefits of today’s modern maquiladora program, Tetakawi can help. Reach out today with questions or to get started. Together, we’ll work to make manufacturing in Mexico a reality for your company.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.

Table of Contents:

- What are maquiladoras in Mexico?

- The benefits of operating a maquiladora in Mexico

- 1960s-1980s: The origin of maquiladoras

- 1970s-1980s: The growth of maquiladoras in Mexico

- 1990s-2000s: NAFTA’s impact on maquiladoras in Mexico

- 2000s-2018: Modern maquiladoras under IMMEX

- 2019-2020s: Growth of maquiladoras today

- Setting up a maquiladora in Mexico?