When considering manufacturing options, nearshore manufacturing emerges as a strategic choice for companies seeking proximity to their home market while still benefiting from cost advantages. Unlike offshore manufacturing, which involves moving production to a distant country, nearshore manufacturing entails relocating production to a nearby, lower-cost country.

Mexico, with its close geographical proximity to the United States, has become a prime destination for nearshore manufacturing operations. By leveraging Mexico's skilled labor force, competitive labor rates, and well-established industrial infrastructure, companies can achieve cost savings without sacrificing logistical efficiency or quality control. Additionally, nearshore manufacturing in Mexico allows for easier collaboration, shorter supply chains, and reduced transportation costs, making it an attractive option for companies looking to optimize their manufacturing footprint while remaining close to their target market.

Below, we provide an average of these and other typical Mexico manufacturing costs. While these averages are no substitute for a complete cost analysis, this information can provide a starting point for site evaluations.

Regulatory Costs Associated With Manufacturing in Mexico

Setting up a new facility in Mexico will require you to incur some one-time start-up costs. For example, companies that opt to incorporate on their own will face costs for incorporation and fees for certain registration activities. There are also customs permits needed to get your raw materials and finished products in and out of the country, as well as potential operating permits. Some of these fees can be avoided by choosing to manufacture under the IMMEX program as part of a Shelter Company, which already has the necessary registrations and certifications.

Also, it's essential to factor in ongoing taxes. Companies may face a 16-percent value-added tax on shipped materials and equipment into Mexico. Those that opt to register under the IMMEX program and obtain an IVA Certification can avoid that cost in many cases. However, all companies must factor in Mexico's corporate income tax of approximately 30 percent, a state payroll tax ranging between 1.8 to 2.9 percent, and a real estate tax of 0.1 to 0.5 percent.

Average Labor Rates in Mexico

It can be difficult to come by labor rates in Mexico, where wages and benefits can vary by region, municipality, and even by neighborhood. In addition, wages are expressed as a daily rate of pay across 365 days. This gross daily pay rate is meant to help employers calculate benefit entitlements, but it can be confusing for employers used to an hourly rate.

Average wages in Mexico for unskilled direct labor are about USD $4.86 per hour, fully fringed. Semi-skilled labor may be closer to USD $5.20 per hour. More skilled direct laborers, such as CNC machinists, may earn in the range of USD $8.16 per hour.

Location will be a significant factor impacting expected costs. Companies in metropolitan regions or closer to the northern border, where demand for manufacturing skillsets is highest, should expect to pay more than rural areas with a much more expansive hiring pool. For more information about labor costs in Mexico, listen to this podcast below:

Industrial Real Estate Costs in Mexico

Manufacturers with unique needs may opt for a build-to-suit facility in Mexico—and the sky is the limit on those costs. However, many manufacturers will find that Mexico has ample industrial space available for lease. New industrial construction remains hot in order to meet continued demand. As a result, it is possible to lease a typical class A building within an industrial park for somewhere between USD $0.41 and $0.70 per square foot each month in many markets.

This provides a competitive edge when compared to the United States, where space is tight, and national industrial in-place rents have skyrocketed to an average of $0.79 per square foot.

It is typical for industrial parks in Mexico to charge an additional USD $0.015 to $0.03 per square foot each month for maintenance of common areas. On a triple net lease, expect to add 2.5 to 6 percent to cover the costs of taxes, maintenance, and insurance.

This additional cost won't include any upgrades that may be necessary to support a company's unique manufacturing needs. Upgrades might consist of adding more power, changing out lighting, or adding appropriate fire protection, safety signage, and ventilation to accommodate specific hazards. Companies should also add in the cost of furniture or other office modifications that won't come with the bare building.

This podcast provides a more comprehensive breakdown of real estate costs in Mexico:

Mexican Utility Costs

Utilities will impact your total cost to manufacture in Mexico, so it's essential to budget for these costs upfront. However, it’s also important to evaluate accessibility. Not every location will have the infrastructure in place. That’s one reason well-developed industrial parks are popular for manufacturers in Mexico.

Utility costs to consider include the following:

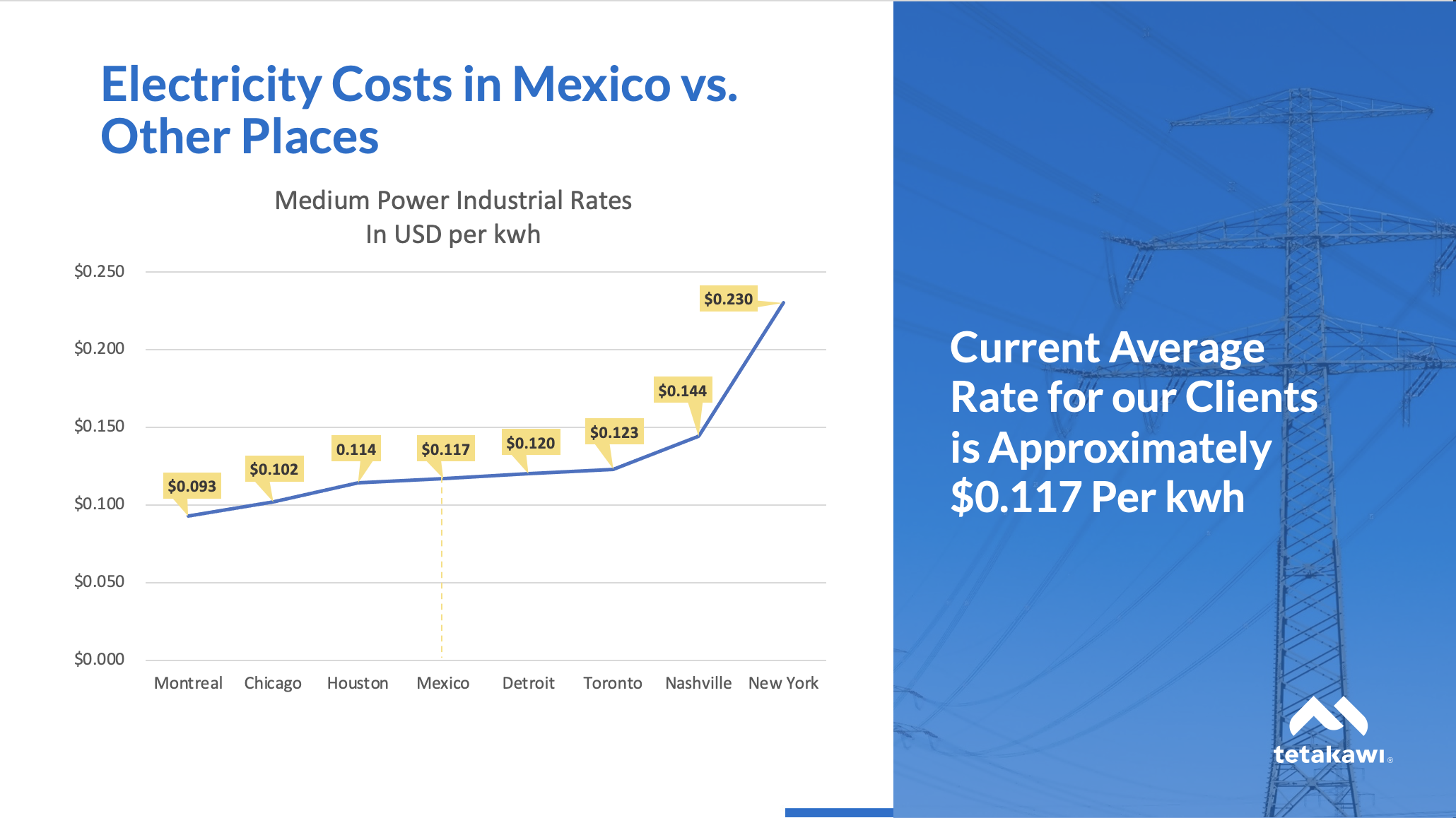

- Electrical: On average, electric costs fall around USD $0.117 per kWh for manufacturers. That puts it just above the average costs for electricity in places like Montreal and Chicago, but this higher rate is generally more than offset by other utility costs and overall lease rates.

- Natural gas: On average, natural gas rates in Mexico will fall around USD $0.034 per kWh for businesses. This will, of course, vary based on region and monthly volume. Overall, it’s a highly competitive rate compared to rates around $0.044/kWh in the U.S., $0.056/kWh in the UK, and $0.140/kWh in Germany.

- Water and sewer: A cost of USD $0.007 per gallon is relatively typical for water in Mexico. Manufacturers should check with local providers to understand any restrictions that may impact usage and regulations around water discharge.

- Internet services: These costs are comparable to other countries. For a 8 Mbps line in Mexico City, a monthly internet connection might cost approximately USD $20. While connectivity continues to grow, some rural areas may not be as well connected as established industrial centers.

- Telephone: A primary line may cost about $20 per month and may go up depending on the number of lines required. Talk to local providers to factor in the cost of installation.

Ongoing Operational Costs for a Factory in Mexico

While ongoing utility costs will be factored in as operational costs, there are some additional items to consider to keep a facility in Mexico running smoothly. For starters, whether or not your site is automation intensive, there will be equipment that needs ongoing maintenance or replacement. You'll want to factor in any specific equipment required for the upkeep and calibration of machinery, as well as cleaners and other consumable supplies needed for overall facility maintenance.

Additional costs will include the initial training time needed for new employees to reach the expected production standard. Start-up operation costs may also include some wasted product as machinery gets up and running, as well as the cost of trainers. If managers are trained in another country, the company will need to budget for trainers' salaries as well as food and lodging costs.

Other operational costs might include such things as safety gear, medical supplies, and office supplies. Some of those costs may be budgeted for based on your current operational costs.

Transportation and Logistics Costs

After labor rates, transportation costs are the next most attractive advantage for manufacturers considering a factory in Mexico. Proximity to the U.S. border by highway, rail, and ship provides manufacturers with significant cost benefits compared to transport from popular low-cost manufacturing locations in Southeast Asia in particular. For example, companies can expect to pay more than $3,000 to ship a container from China to Los Angeles. Shipping rates from Mexico are far more variable, given the wider range of options for shipping goods.

It is important to know that companies are required to work through a Customs broker who will handle cross-border requirements. There may be additional costs to factor in for these services.

Estimate Your Mexico Manufacturing Costs

Comparing your costs in your home country today against projected savings by moving to Mexico is the only way to feel secure in your cost savings. While this information will help you begin to prepare for the costs of a new manufacturing operation, it's only the first step. For a complete estimate of what it costs to manufacture in Mexico, reach out to Tetakawi today.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.