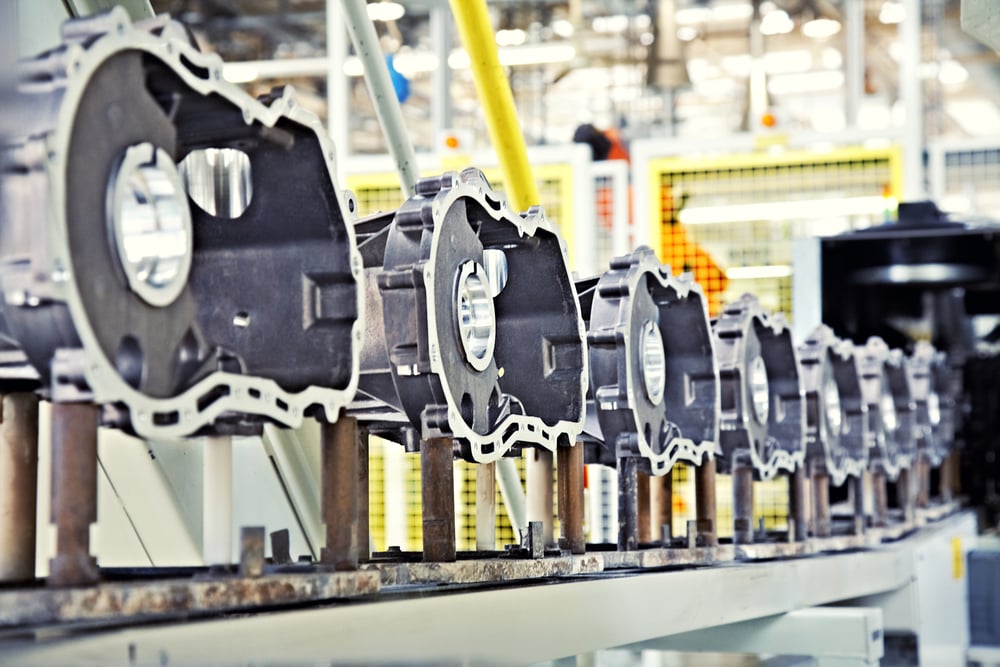

In today's interconnected world, global supply chain integration plays a pivotal role in the decision-making process for manufacturers eyeing Mexico as their next production hub. As companies navigate the complexities of international trade, the seamless integration of supply chains across borders becomes paramount.

By establishing operations in Mexico, manufacturers gain strategic proximity to major consumer markets while capitalizing on the country's robust infrastructure and skilled labor force. This integration enables streamlined logistics, reduced lead times, and enhanced agility in responding to market demands.

Moreover, Mexico's participation in various trade agreements fosters a conducive environment for businesses seeking to optimize their supply chain networks. From sourcing raw materials to delivering finished products, global supply chain integration is not just a buzzword but a strategic imperative driving success in the competitive manufacturing landscape.

Choosing Where to Set Up

Manufacturers evaluating site locations in Mexico find there is ample quality Class A industrial real estate available for lease. In fact, credit rating agency Fitch Ratings is forecasting strong growth in Mexican industrial real estate performance well beyond 2023. That’s because the strong demand for manufacturing facilities is being well supplied, as new facility construction is keeping pace in most regions.

As manufacturers evaluate their real estate options, many find themselves weighing the advantages of a traditional industrial park or Manufacturing Community compared to building their own facilities. Manufacturers new to the maquiladora system may not be aware that Mexico is home to world-class industrial facilities that offer highly competitive amenities and features.

According to the Mexican Association of Private Industrial Parks (AMPIP), an industrial park in Mexico offers all the services, permits, and infrastructure required for manufacturing, distribution, and related logistics. This includes basic services such as water, electricity, and telecommunication, as well as other more manufacturing-specific services such as natural gas, water treatment facilities, railway spurs, and other amenities. These parks are located near main trade routes and urban areas for easy access to markets, supplier networks, labor, and related services. In addition to accessibility and service, many industrial parks in Mexico offer a range of forward-thinking amenities designed to position their tenants for success.

The future of industrial parks in Mexico

Companies bringing their manufacturing expertise into Mexico have plenty of insight to shape their factory operations. Companies with less experience will find that many facilities offer standard infrastructure in support of unique industrial needs (although representatives should always tour a facility to determine suitability rather than accepting conditions set out in the lease). But with all of the transformation happening in manufacturing today, you may be wondering what other advantages are available for companies investing in a factory in Mexico.

While companies are limited only by vision and funding, below, you’ll find a few examples of the advantages companies are incorporating within their Mexico facilities today.

1. On-Site Training

Manufacturing workforce development is a priority in Mexico, with state and federal governments investing in technical training and engineering-focused degree programs at a number of universities. In fact, regular training is a requirement for all manufacturers with 50 or more employees.

Many manufacturers find they can partner with local training programs or schools to help employees bolster their skills. However, some manufacturing communities provide dedicated training space to help bring employees, apprentices, or prospects up to speed on technical skills. For example, the Advanced Technology Training Center (CEFTA) within the Roca Fuerte Manufacturing Community in Guaymas provides a safe space in which individuals can gain hands-on experience with precision machining. This dedicated training space can speed the onboarding process by helping trainees advance in highly specialized skills in a low-stress environment.

For manufacturers needing to keep pace with the latest production techniques, a dedicated training area may be a value-added factory option to consider.

2. Connected and sustainable infrastructure

As noted above, industrial park owners tend to oversee that their tenants have seamless service for basic utilities as well as more manufacturing-specific services. Owners also are responsible for maintaining security measures, which may include gated access and video surveillance.

Not all regions offer the same easy access to industrial infrastructure, so it is important to always important to ensure that your needs can be met before leasing. However, as access to these services grows across Mexico, many factories are also taking steps to develop sustainably. As more organizations incorporate decarbonization goals in their environmental, social, and corporate (ESG) governance, facilities are becoming available that can meet these expectations.

AMPIP notes that many industrial parks in Mexico are in programs that aim to reduce ecological damage through improvements to water, energy, and waste management systems. These include PROFEPA’s Clean Industry Certification and AMPIP’s Green Industrial Park program.

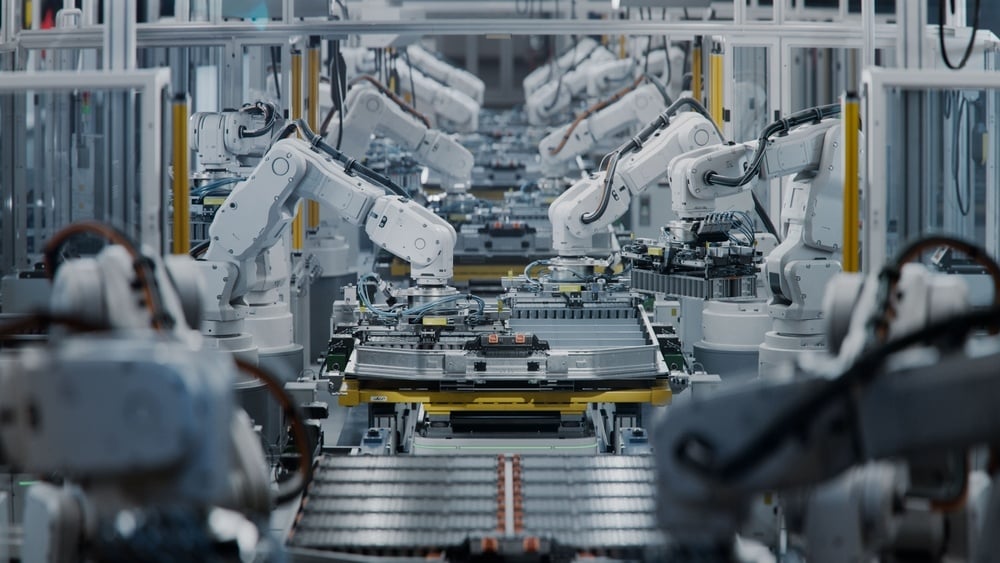

3. Smart factories

Manufacturers in Mexico are increasingly positioning themselves to operate Industry 4.0-aligned smart factories. As a result, AMPIP has set out a goal of having by 2025 at least one-third of all industrial parks in Mexico fitted with high-added-value infrastructure that can attract Industry 4.0 manufacturers.

So, what does that mean? According to AMPIP’s Roadmap Towards a New Generation of Smart and Sustainable Industrial Parks, that means greater access to skilled workers able to use technologies for collecting and analyzing big data. It means greater incorporation of automated processes enabled by the Internet of Things (IoT), collaborative robots, virtual and augmented reality, additive manufacturing, and other technologies that stand poised to transform production.

This Industry 4.0 prep begins with a commitment on the part of local companies and government to create conditions right for supporting advanced manufacturing. This can be seen in programs such as the state of Nuevo Leon’s 4.0 Initiative, which aims to create an ecosystem that strengthens training and resources around advanced manufacturing technologies and materials. Some of Mexico’s more advanced factories are taking steps to be a part of this ecosystem.

4. A range of workforce amenities

Many of Mexico’s industrial parks offer amenities that help put their tenants in a position of strength when it comes to recruitment and retention. This may include entertainment areas such as sports complexes and rec fields, as well as care facilities such as medical centers and daycare. Having all of these amenities on-site can serve as a powerful enticement for employees by creating an environment where people want to spend their day.

The Zapa Manufacturing Community in Saltillo, Coahuila, offers features that support not just employees but also their families. This includes amenities such as a soccer court, sports tournaments, and a soccer school for employees' children, among other family-oriented events throughout the year.

5. Safe environments

Safety is often a concern for manufacturers new to operating in Mexico, but it’s also one of the leading priorities for many industrial parks. Many manufacturers can rest assured in the safety of their industrial park by looking for organizations that with OEA certification.

The Authorized Economic Operator Program, or OEA, was implemented by the World Customs Organization to secure the international supply chain. Certification demonstrates to Customs authorities that a manufacturer is safe and reliable, as it meets 11 requirements outlined by the program. These requirements establish safety and security across all aspects of operations, including physical security at the facility, access control processes, process safety, and personnel security. This designation is not necessarily easy to achieve, which is why it helps set industrial parks apart.

6. Logistics and administrative support

Of course, one of the biggest advantages of an exceptional industrial park is the on-site services that are available. This ranges from basic business centers to all-inclusive shelter services, which help companies with administrative, HR, and customs support. With this help available on-site, manufacturers can focus on their core offering: manufacturing excellence.

Build your ideal factory in Mexico

Of course, not all industrial parks are the same, and manufacturers should tour facilities and ask questions to ensure their future factory is the best fit for today’s needs and future expansion. But, with a clear list of needs and expectations, there’s no reason that manufacturers shouldn’t dream big when it comes to building a competitive factory for the future.

If you’re ready to find the right factory for your manufacturing needs, Tetakawi can help. Contact us today.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.